Hyperion Detonation Technology

A platform for the production of products that is changing the landscape of nanotechnology

The Hyperion method is an example of an elegant synthesis. Fill a chamber with hydrocarbon and oxygen, ignite the mixture with a small spark, and voila, graphene is formed.

PATENTED IN 2016

High-yield production via detonation is the founding technology for HydroGraph.

The detonation system produces the highest purity, most consistent graphene with the smallest environmental footprint in the industry in a process that is modular and scalable for clients. HydroGraph’s graphene provides atom by atom customizability and in tonnage amounts with near perfect batch to batch consistency. We ignite material change.

The Hyperion System

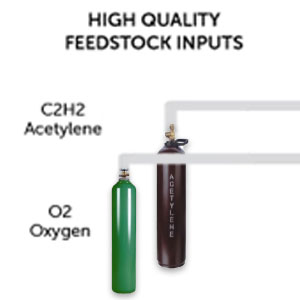

Readily available

feedstock

HydroGraph’s Hyperion System will change the landscape of nanotechnology, beginning with graphene and followed by hydrogen and an array of other valuable materials

Graphene

We produce the highest-quality, purest, most consistent, most easily integrated graphene on the market. The same high-quality standards will apply to all other materials produced by HydroGraph, including soon-to-come hydrogen.

Detonation Chamber

Conserves energy and prevents emissions. Ideal for commercial deployment: modular, scalable, customizable, decentralized, and eco-friendly.

Graphene Properties

STRONG

FLEXIBLE

IMPERMEABLE

THERMAL CONDUCTIVITY

TRANSPARENT

ELECTRICAL CONDUCTIVITY

Graphene is 200 time stronger than steel, yet it is extremely flexible and can bend and stretch to 120% of its original size. This allows many applications in composite materials like rubber, plastic, aluminum & concrete. Its durability is great for coatings, additives and wearable technologies. It would be a great fit for bendable screens, as it is also thin, light and transparent. Graphene can conduct electricity at 1000 times the capacity of copper and electrons move through it at nearly light speed. Imagine the possibilities of more efficiency for computer chips with improved speed and longer lasting battery life. And, graphene is impermeable – hydrogen atoms cannot penetrate its structure, a great feature for water purification, gas storage and hydrogen fuel cells.